|

| |

|

| |

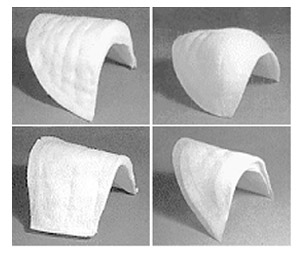

GARMENT INTERLININGS

Nonwoven garment Interlinings are made from 100% polyester staple fibers mechanically bonded, generally

available in various weights depending on the applications.

The property characteristics of a nonwoven interlining ensure that it fulfils the required function.

|

|

|

In general, the functions of a nonwoven interlining can be divided into three main groups:

|

|

|

|

|

Additional Functions of Interlining: | |

| |